Why So Many Brands Struggle to Find the Right Factory — And What You Can Do About It

If you’ve had to switch factories more than once, you’re not alone.

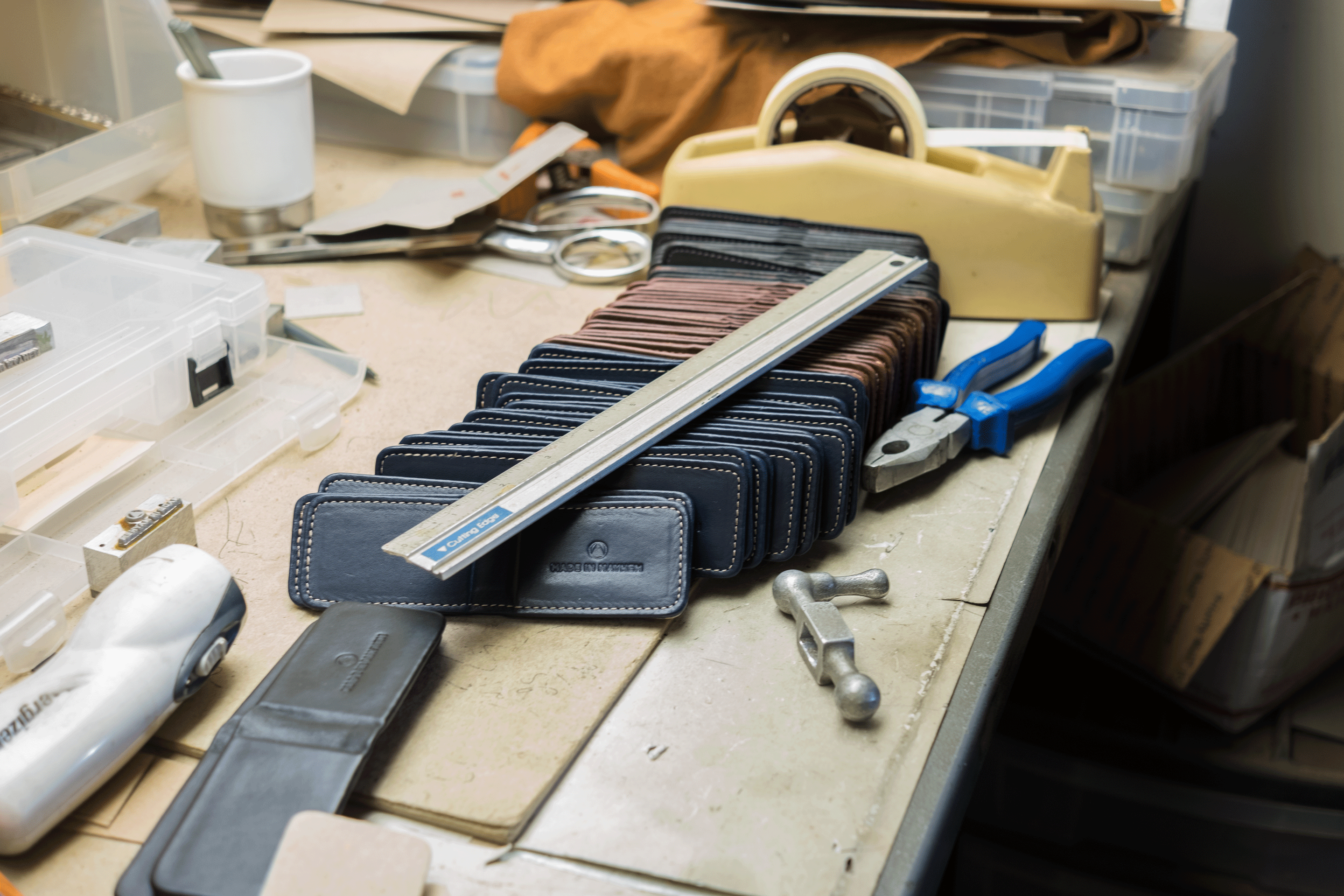

For emerging and mid-sized leather goods brands, one of the biggest challenges isn’t designing the product — it’s finding and keeping the right production partner. It’s frustrating to finally think you’ve found a match, only to face the same issues again: missed deadlines, poor communication, and quality that doesn’t meet your standards.

So why does this happen — and what can you do differently to avoid constantly starting over?

The Real Reasons Brand–Factory Relationships Fail

1. Misalignment on Capabilities

Not every factory is equipped to handle every type of product. A workshop great at hand-sewn belts may struggle with structured bags. When factories overpromise, brands are left to deal with disappointing results or costly delays.

2. Lack of Communication Structure

If you're relying on inconsistent email threads, unclear WhatsApp messages, or a rotating team of contacts, issues are almost inevitable. Without a clear project manager or system, production quickly derails.

3. No Scalable Process

What worked for 100 units may fall apart at 1,000. Many smaller factories aren’t set up to scale with you, and growing brands often outpace their factory before they even realize it.

4. No Shared Expectations

When details aren’t confirmed in writing — like materials, timeline, pricing, or revisions — assumptions get made. And assumptions lead to tension, remakes, and friction.

What to Do Before Choosing a New Factory (Again)

If you’re gearing up to search for another manufacturing partner, consider these steps before making the leap:

-

Document your non-negotiables — What are the absolute musts for your business (e.g., lead time, communication cadence, pricing transparency)?

-

Request references and samples — Don’t just take a factory’s word. Ask to see what they’ve made — and for whom.

-

Start small, but structured — Run a well-defined sampling process before committing to production. Treat it like a test run, not a trial-and-error phase.

-

Vet their capacity honestly — Ask how they scale, what their minimums are, and what happens if you need to double output next season.

-

Clarify who’s managing what — Whether it’s you or a third party, someone needs to own the production timeline and accountability.

What a Reliable Production Partnership Looks Like

Once you’ve found the right fit, your production partner should function like an extension of your team. That means:

-

Clear roles and a primary point of contact

-

Shared visibility into timelines, materials, and costs

-

Regular updates with no surprises

-

Respect for your product vision and brand standards

When you have that, you free up time and energy to focus on the parts of your business that need you most — like design, marketing, and growth strategy.

In Summary

If you’re constantly starting over with factories, the problem isn’t you — it’s the system. Most brands don’t need a new factory every time something goes wrong; they need a better process for finding and managing the right one.

Invest time upfront, define your needs clearly, and make communication a priority from day one. That’s how you avoid factory hopping and build a supply chain that supports your growth for the long haul.